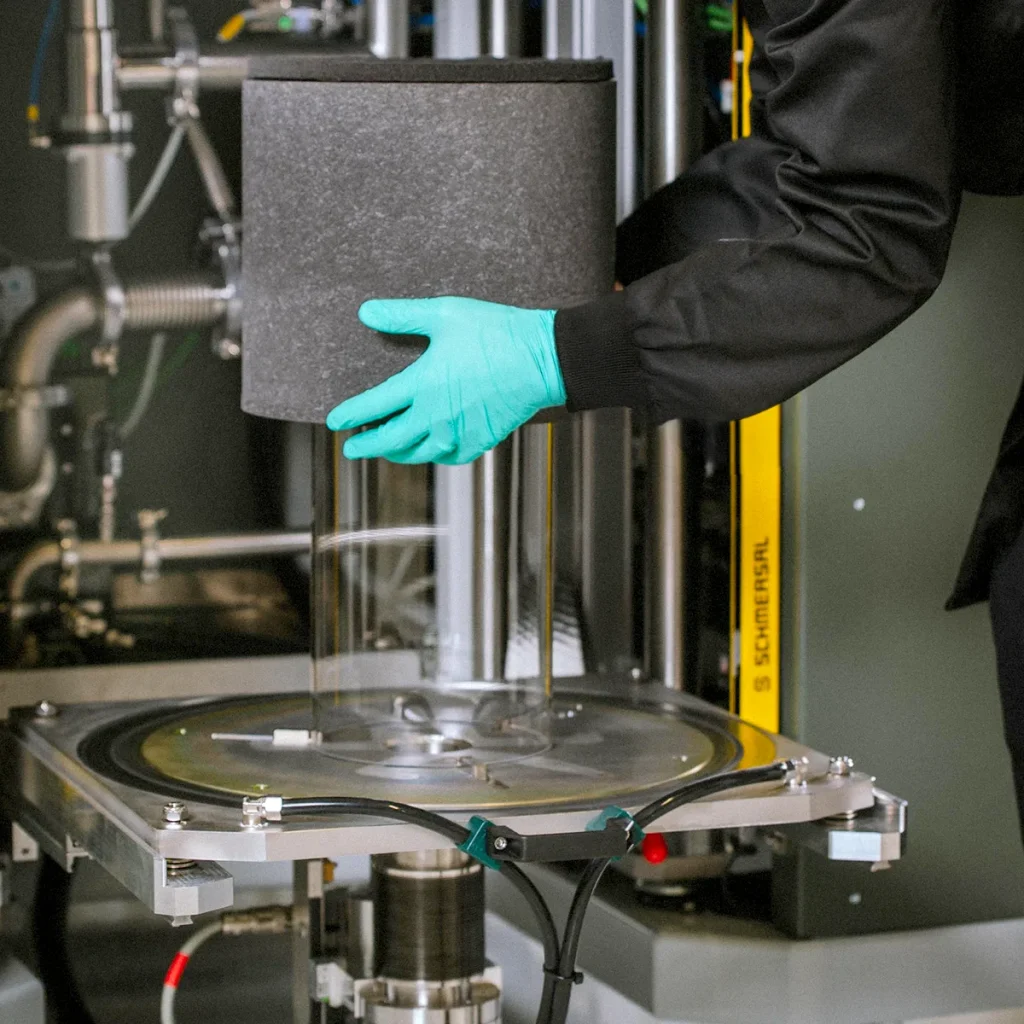

We are proud to present our High Temperature Vacuum Furnace Xforge HT!

The Xforge HT provides extraordinary temperature performance, capable of reaching extreme temperatures with exceptional stability. The advanced pressure and gas management system allows for meticulous control of the processing environment during intricate heat treatment operations. The system features an intelligent, user-friendly software interface that allows researchers and engineers to design and execute thermal procedures with unprecedented ease.

A Versatile Tool

The Xforge HT represents a breakthrough in high-temperature thermal processing systems. Designed for precision and performance, this system delivers exceptional capabilities for demanding scientific and industrial applications.

The Xforge can be used over a wide temperature range but its uniqueness is even more obvious when higher temperatures are required.

Example of Applications

- Additive Manufacturing (AM)

Supporting post-processing heat treatments for 3D printed parts, enhancing material properties and performance. - Sintering and Powder Metallurgy (PM)

Facilitating the consolidation of metal powders into solid components with controlled density and microstructure. - High temperature testing

Enabling materials characterization and quality assurance under extreme conditions. - Diffusion coating (e.g. surface hardening)

Assisting in surface hardening processes to improve wear resistance and durability of components. - Diffusion bonding

Aiding in the solid-state joining of similar or dissimilar materials for advanced engineering applications.

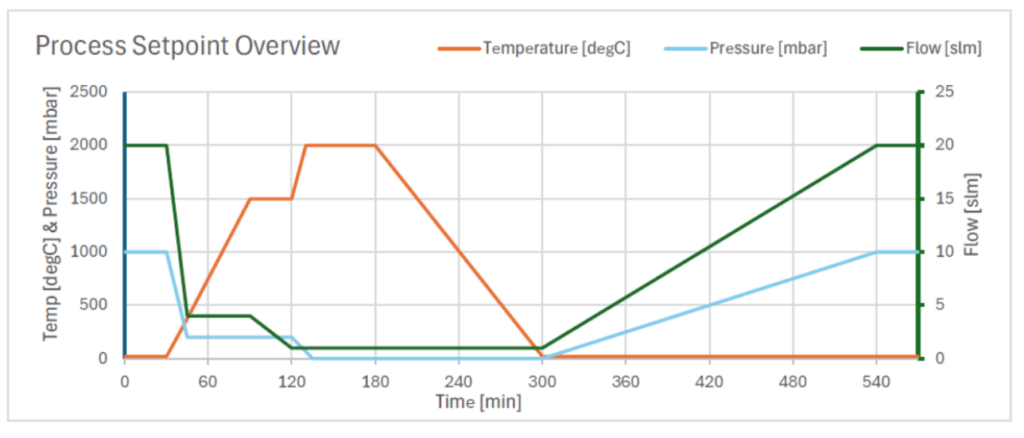

Freedom to Design and Refine Your Processes

The Xforge HT has a wide Processs Window in which the user can excercise a tight control over the process.

Control the Process Temperature*

- Temperature range: 100 – 3000 °C

- Max Heat up rate: 30 °C/min

- Max cool down rate (not yet optimized): 15 °C/min

- Temperature stability: ± 1 °C

Control the Process Pressure

- Vacuum levels: 1 – 950 mbar

- Vacuum stability (steady state): ± 0.5 mbar

Control the Process Gas

- Qualified gases: Argon, Nitrogen, Hydrogen

- Flow rates: 0.02 – 20 slm

- Flow accuracy: ± 1%

Control the Changes of Process Parameters

- Interface facilitating real time editing of parameters

- Develop processes with multiple steps using recipes:

– Save and load recipes.

– Edit recipes

– Conditional programming of process steps

– Recipes of up to 100 command steps.

(facilitates several heat up and cool down within the same run) - Real time logging of process parameters

- Customizable access levels

- Online login facilitating remote monitoring and controlling

*Depending on the object

The Tool for High Temperature Materials

Xforge is able to process high temperature materials (refractory metals, carbides, etc.) such as:

- Tungsten (W)

- Tungsten Carbide (WC)

- Rhenium (Re)

- Tantalum (Ta)

- Tantalum Carbide (TaC)

- Molybdenum (Mo)

- Niobium (Nb)

- Niobium Carbide (NbC)

If your application area is to process high temperature materials then the Xforge HT is the tool for you!

What we Offer

Order Your Xforge HT Today!

If you need to run Heat Treatment Processes, Xforge HT could be the perfect solution for you.

We’re happy to provide a tailored solution and a personalized quote to meet your needs.

Contact us to explore its capabilities and ownership options!

Heat Treatment as a Service

Need to run a Heat Treatment process but not ready to invest in a furnace yet?

No problem—we’ve got you covered!

Simply send us your parts, and we’ll handle the process in our facilities before shipping them back to you.

Contact us to learn more!

• Broad Temperature Range

• Engineered for Peak Performance

• User Friendly Interface

• Customizable Coil Design

• Accurate Process Pressure

• Premium Quality Components

• Safe and Simple Operation

• Energy Efficient